I announce the Roller Coaster project at the beginning of the year since it has been an optional part of my gr 12 programme since 2000. Old coasters are in my room. Students are free to look at them. I will sometimes demonstrate them.

The actual project is posted on my web site as soon as the I notice that the rules are up.

The first year was almost a disaster. Students had little

idea what they were getting into - too little too late was the motto for

most of them. The biggest problem was supporting the track.

To combat this problem (and the late submission of coasters),

I did the process evaluation timelines that I insist for all other gr 12 summative projects.

This is an informal conference with the group concerning

what they have done - what materials they have considered, what have they

built, what theme, have they read the rules... These conferences do not

begin until January or February - this year it was late February.

The key to the coasters success was experimentation. I

encouraged students to window shop at the hardware store and check out

interesting materials for track. Many students purchased small amounts

of track material to play with.

From experience I was able to discuss various track materials

with them - the basic 2 options plastic tubing and wire. I outlined some

of the problems encountered in previous years. I have provided this page

to give you some of this information. Not all students choose these options.

Most of the building can be done in a weekend, IF all

the materials and tools are ready to use. Experimentation with materials

MUST be done before the start of building. This includes track material,

connectors (railway ties), and method of loop construction.

Decoration can be left to the end; however, a theme should

be developed earlier and integrated into the building stage. This allows

for tunnels and painting to be done before the track is complete. Take

a look at "Wrath of Ra" and "BBQ". Some of themes have been created after

the fact when the coaster is complete and it suggests a theme to the builders.

Leave time to decorate and fine tune.

(Purchase the popsicle sticks from the Board of Education

if possible - the TDSB price is $2-3 for 1000 compared to $2 for 200)

| Track Material |

click to enlarge

pics

|

| Plastic Tubing provides a smooth, quiet ride for

the ball. It is easier to work with and can be found in most large hardware

stores. It can be pinned or glued. Joining tubing can be done using small

dowels and inserting them into the tubing. Small loops are hard to do.

Perhaps the lowest friction option - but check it out yourself. |

|

| Metal Wire is difficult to keep straight and smooth. If you

bend it, then the bend stays there and throws the ball off the track. Soldering,

welding and glueing are a few ways to connect wire. If joining the wire

is difficult, then a "Y" can be used to collect the ball on the next section

of track - I'll see if I can find a picture of this.

The kids say "hanger wire" which can be purchased straight in 12' lengths is cheap and easier to work with than those coiled wires. I like the sound of a metal track - but that spells energy loss. |

|

| Copper Tubing has a great sound. I am told it is easy to work with, but watch those incorrect bends - this material is almost impossible to straighten. Works well with welding - but glues works too. |   |

| Curtain Rod is used in the Fifth Dimension. Notice the careful cuts to make the turns. Many loops can be made in sequence - a method which seems to be perfected by St. Mary's Catholic S.S. |

Look at the loops in this 2007 winner "The Venom" But this one wouldn't work at the competition |

| Chicken Wire is an interesting material used here in the "Wrath of Ra". The 2 parallel wires are already connected together - some bending was needed to provide the correct rail separation. Tubing was then placed over the wire to provide a smooth running surface. Notice the wire has been spray painted gold. |  |

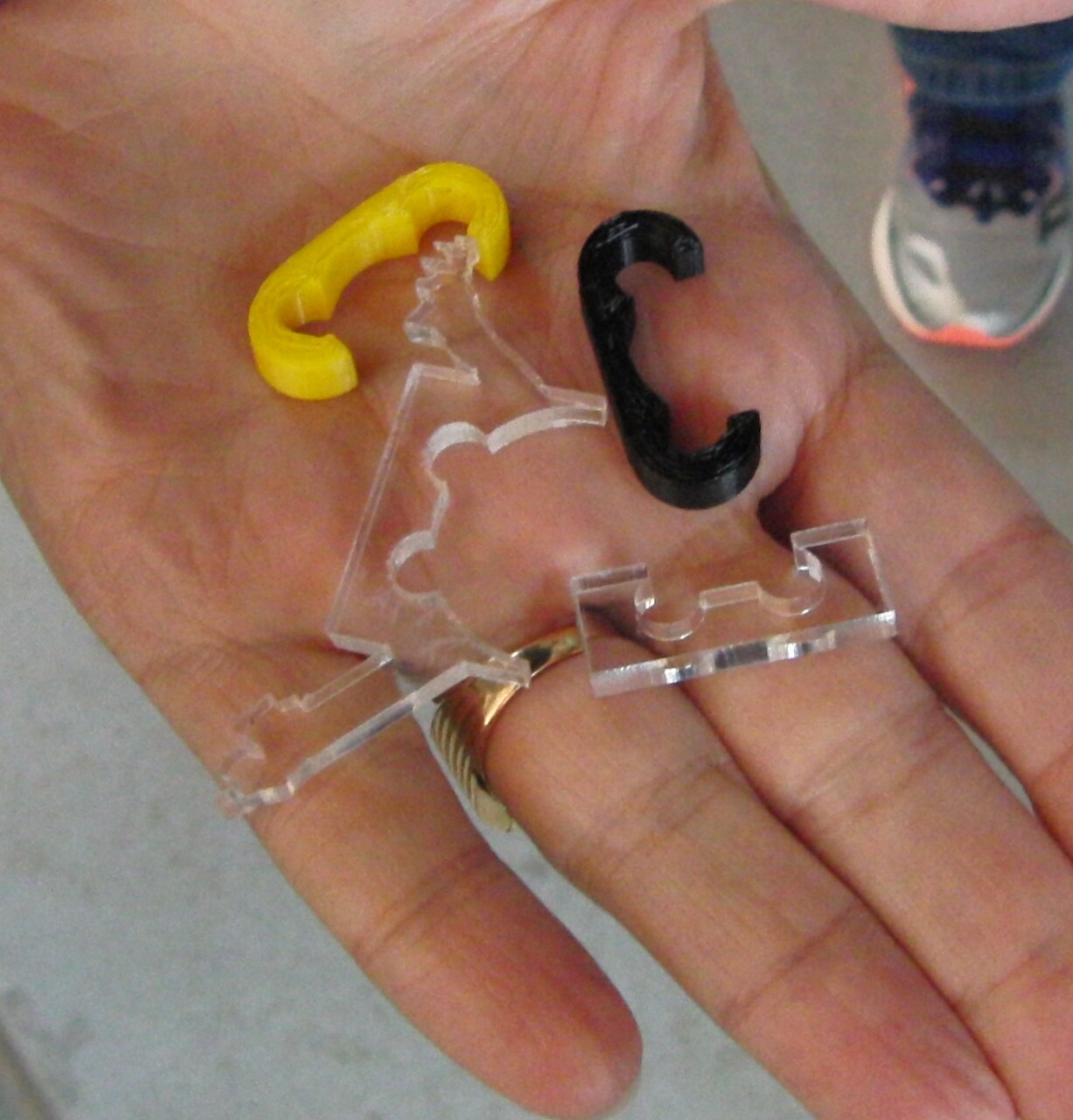

| Connectors and spacers 3D print or cut spacers |

|

| Hot glue guns are the most popular - but they aren't a permanent solution. The craft glue is weak. Use the heavy duty stuff but even this falls apart. Either way, there are all those drips and spider-web-like tendrils which mess up your track. Every coaster that has used a glue gun has encountered the problem of the glue coming undone. White glue or superglue can be used AFTER the track is setup to provide a more permanent and secure bond. | |

| Welding and Soldering take special care and skill. Practice. | |

| Vertical Supports need to be thought about right at the beginning. They should be solid and immovable. Having said that, look at "Paper Dream" where the supports are made of paper - this one had a marvelous wobble as the ball went down. Wither way - how do you support the track? Think of a a secure and consistent manner. | PaperDream link |

| Loops and corkscrews create a problem every year. A corkscrew

is a series of vertical loops - but fractional loops are permitted.

Measure the maximum inner diameter.

What is the best shape for a loop? |

The wires are

glued to some embroidery hoops. The wires are

glued to some embroidery hoops. |

| Temperature does effect the running of the coaster in strange

ways. Metal contracts when it is cold. This could leave your roller coaster

unworkable as it did "Hard Drive".

Even the plastic track seems to be very susceptable to temperature variation. Some of my groups swear that their coaster only works with the lights dim. What is the effect of temperature on the coefficient of friction on the track? (Is there any? Check it out?) |

Keeps those tracks clean. Dust and sand (and other materials used as decoration) can get on the track and cause the ball to jump. Hey, but don't keep the track too clean - if you decrease the friction too much the ball slips instead of rolling. (My hypothesis - another thing to check out!) |

| The right ball maybe very important to your coaster. The shiny

new balls sometimes are worse than the old "dirty" balls. My

thought is that the shiny balls have a lower kinetic friction and tend

to slide instead of roll. There was a considerable difference between balls.

This would make a good ISU...

For my students, the most popular balls are 13 mm (Sargeant Welch)and 16 mm (Boreal) steel balls. Have them mark down what size ball they use. And have a "cup" to store the ball near the top of the coaster and a contained stopping point at the end. Remember that ball retreival is necessary when the ball comes off the track... don't let the ball get lost in the woods (decoration). |

|

| Remember that in competition anything that can go wrong will go wrong - Murphy's Law. If it doesn't, consider yourself lucky. | In 2002, a group of students constructed a coaster with a technical merit score of almost 22 million - (22 - 4 cm loops and 90 seconds) which I verified at school. At Wonderland it only worked once (just before judging started). Was it the leveling? No they had a level attached to the base for this purpose. Was it the temperature? Likely - it was 15 degrees colder and their metal (copper pipe) supports would have contracted. The almost level portions of track just didn't work. |

| Bring enough stuff to repair and level your coaster. Adjustable feet? A level! Extension cord, glue gun, tape,... You will NOT have much time to setup your roller coaster! |